CATEGORIES: Building Products, Case Study, Cost Reductions, Improved Efficiencies, Manufacturing

HVAC Materials Manufacturer Increase Revenue

The Challenge

LL Building Products was not operating at its full potential at the time it was acquired. As a primary supplier to Home Depot, LL had grown quickly to keep pace with the home improvement giant’s expanding operations. Unfortunately, this rapid growth also magnified the shortcomings of LL’s management infrastructure, resulting in communication breakdowns, widespread inefficiencies, and poor employee morale.

About the Client

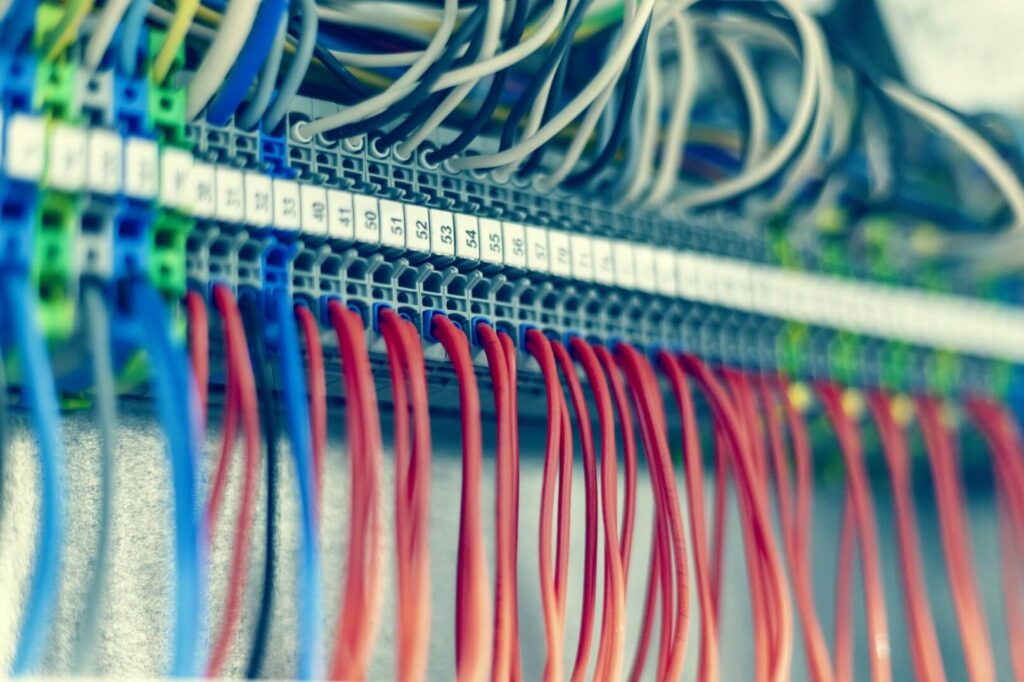

LL Building Products is a manufacturer of ventilation systems and HVAC materials—products sold in tandem with roofing supplies — making this new subsidiary a natural complement to GAF’s business.

Financial Results Snapshot

DB&A Delivered

- 20% increase in efficiency

- 50% reduction in temporary labor requirements

- 67% average decrease in scrap

- 45% reduction in inventory, resulting in $3,000 monthly savings on outside warehouse costs

- 29% reduction in overtime